Maintenance

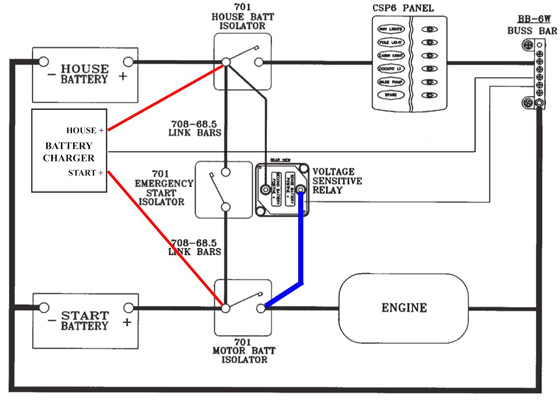

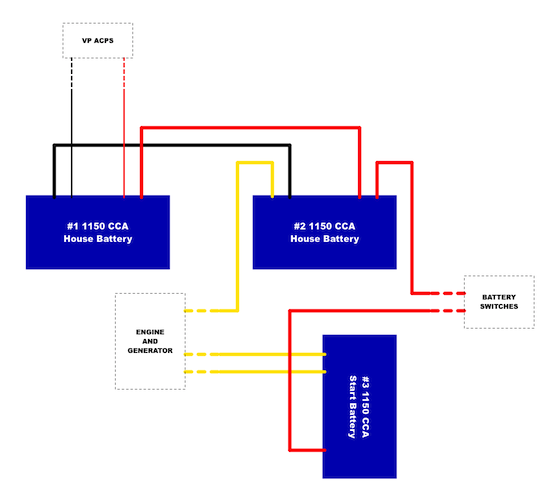

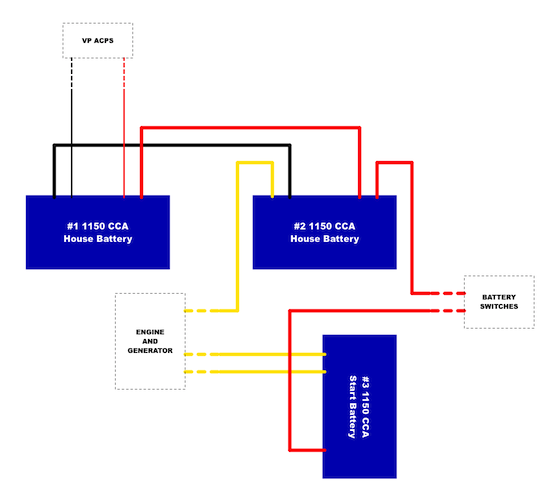

THE VSR CONNECTIONS … MEMO TO SELF

01 November 2014 00:00

Double check the connections on the boat … red and blue wires. This is how it is supposed to be done to isolate batteries when charging with battery charger powered by shore power or generator.

MEMO TO SELF … NEW BATTERIES INFO

01 July 2014 00:00

3x AGM DieHard Platinum Marine 31M 1150CCA aka ODYSSEY 31M-PC2150

All three batteries purchased in April 2014 and deployed in June 2014.

Dimensions

• Height (in.): 9.5

• Item Weight (lbs.): 75

• Length (in.): 13

• Width (in.): 6.8

Battery Type

• Group Size: 31M

• Overall Type: Deep-cycle

• Battery Design: Absorbed Glass Mat

• Number of Cells: 6

• Container Material: Polycarbonate/polyester

• Maintenance: Maintenance Free

Power Ratings

• Amp Hours at 20 Hour Rate: 100

• Capacity Amp Hours at 10 Hour Rating: 92

• Cold Cranking Amps (CCA at 0 deg.F): 1150

• Reserve Capacity (RC): 205 min.

Warranties & Coverage

• Free Replacement Warranty Term: 36 months

All three batteries purchased in April 2014 and deployed in June 2014.

Dimensions

• Height (in.): 9.5

• Item Weight (lbs.): 75

• Length (in.): 13

• Width (in.): 6.8

Battery Type

• Group Size: 31M

• Overall Type: Deep-cycle

• Battery Design: Absorbed Glass Mat

• Number of Cells: 6

• Container Material: Polycarbonate/polyester

• Maintenance: Maintenance Free

Power Ratings

• Amp Hours at 20 Hour Rate: 100

• Capacity Amp Hours at 10 Hour Rating: 92

• Cold Cranking Amps (CCA at 0 deg.F): 1150

• Reserve Capacity (RC): 205 min.

Warranties & Coverage

• Free Replacement Warranty Term: 36 months

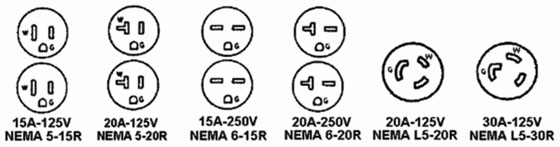

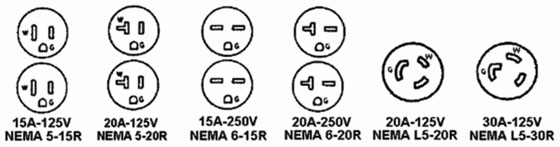

PLUGS, OUTLETS, AND CHEATERS

01 June 2014 00:00

An appropriate warning ... the regular household extension cords are rated for 10A to 15A, the "special" household cords are rated for 20A, the marine shore cables are rated for 30A or 50A. Each rating has a different outlet/plug prong configuration for a reason.

Always use the appropriate cord/cable for the outlet prong configuration and you will sleep well. Having said that, there are "cheater" cables and "cheater" plugs called such for a reason. They convert prong configuration from one amp rating to another. When used, one needs to be very conscious of the limitations and consequences.

I do use "cheater" cable when boat is on trailer at home or in the marina for maintenance. My use of power is very deliberate and managed then. I never leave it ON by chance, and I never run a/c system, fridge, stove, microwave oven, etc when on cheater cable ... all individual 120V AC breakers are OFF but only those I need like battery charger and engine compartment heater, for example.

Can be done but very carefully.

Always use the appropriate cord/cable for the outlet prong configuration and you will sleep well. Having said that, there are "cheater" cables and "cheater" plugs called such for a reason. They convert prong configuration from one amp rating to another. When used, one needs to be very conscious of the limitations and consequences.

I do use "cheater" cable when boat is on trailer at home or in the marina for maintenance. My use of power is very deliberate and managed then. I never leave it ON by chance, and I never run a/c system, fridge, stove, microwave oven, etc when on cheater cable ... all individual 120V AC breakers are OFF but only those I need like battery charger and engine compartment heater, for example.

Can be done but very carefully.

PROMARINER PRONAUTICP SERIES

01 January 2014 00:00

Just as a memo to self …

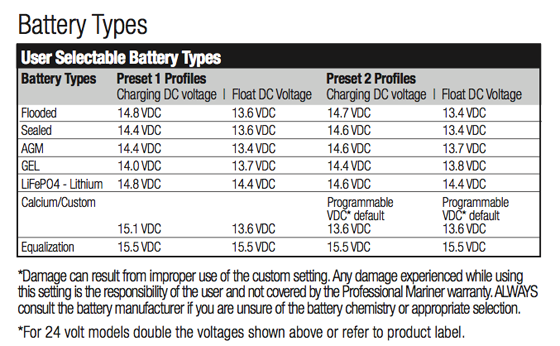

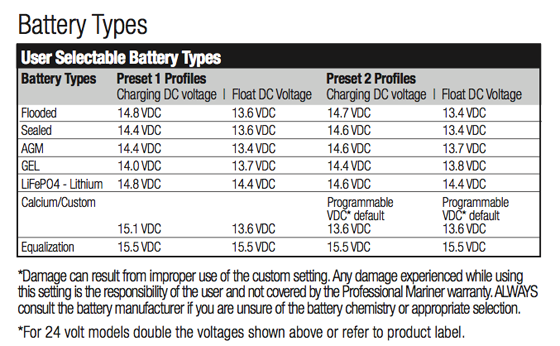

ProMariner NauticP Series default battery charger settings for various battery types.

ProMariner NauticP Series default battery charger settings for various battery types.

STERNDRIVE: PAINT OR NOT TO PAINT?

01 November 2012 00:00

Volvo Penta drive painting procedure

derived from VP 2006 Engine Operator’s ManualPARTS

- Part # 1141562 … Primer

- Part # 827502 ….. Clear Enamel

- Part # 3851219 … Paint, Drive Unit, Silver

- Part # 889968 ….. Drive Touch-up Paint Set: Silver + Clear Enamel

- DuPont 225S Aluminum Refinishing System Step A, Aluminum Metal Cleaner: an acidic metal cleaner and conditioner formulated for aluminum. DuPont 225S effectively removes corrosion resulting from weathering and prepares the surface for the use of DuPont 226S Aluminum Refinishing System Step B, Conversion Coating.

- DuPont 226S Aluminum Refinishing System Step B, Aluminum Conversion Coating: DuPont 226S was developed for use on aircraft, boats, commercial and other vehicles exposed to severe conditions. DuPont 226S chemically stabilizes aluminum, producing a high degree of corrosion resistance and adhesion for paint systems.

- Zinc Chromate, a potential substitute for Dupont 225S and 226S set: for use on aluminum surfaces above or below the waterline, this primer chemically etches into aluminum and forms a corrosion-resistant surface, it helps to create an even, bondable surface for top coat adhesion.

- 3M Scotchbrite Pad Medium

PROCEDURE

1. Remove all marine growth.2. Remove all loose paint and corrosion by sanding or sandblasting. If sandblasting, use an aluminum oxide blasting media with a particulate size of 0.008-0.028 in. (0.2-0.7 mm).

3. Remove all trace of grease and wash with hot water and detergent. Roughen all painted surfaces with medium 3M ScotchbriteTM pad. Rinse thoroughly with water.

4. Treat any bare aluminum with chromate conversion coating. Clean the entire area with an acid cleaner that does not contain fluoride, such as DuPont® 5717. Scrub the surface with 3M ScotchbriteTM pad until it is completely “wetted” with no beads of water.

- NOTE: Fluoride in a cleaner causes a “smut” (dark discoloration on silicon-alloy aluminum castings), and paint will not stick to “smut”. If this happens, sand the surface and start over using a different acid cleaner.

- NOTE: Do not use steel wool. Small pieces of steel wool become embedded in the aluminum and will cause severe corrosion.

5. Rinse thoroughly with water. The area must appear “wetted” or the surface is not clean, and paint will not adhere.

6. While the surface is still wet from rinsing, treat all bare aluminum with DuPont® 226S chromate conversion solution. Brush the chromate solution as required for 2 to 5 minutes to prevent it from drying on the surface. Rinse the surface thoroughly with water and allow to air dry. Follow the label instructions exactly.

- If the chromate is allowed to dry anywhere on the bare aluminum surface, chromic acid salts will form which will prevent paint adhesion and promote corrosion. Sand the surface to bare metal.

- It is best to let the part air dry, but if you must wipe the surface to speed up drying, use lint free wipes not treated with anything that may contaminate the surface. Do not scrub the surface, wipe very lightly.

- Do not blow dry with shop air unless it is completely free of dirt, oil, and water.

- Do not heat the part above 150°F, before painting.

- Do not touch the treated surface with bare bands before painting.

- The part should be primed soon after it dries, or at least within 24 hours.

8. Apply finish coat.

The parts catalogs list numbers for finishing products … see above.

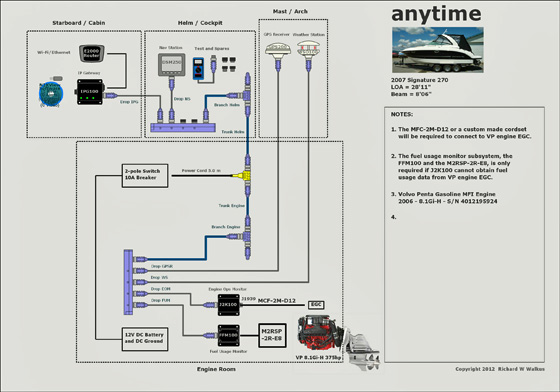

N2K OR NOT N2K?

01 March 2012 00:00